In Defence of Terracotta

Art deco statues – and their composition

Part 1 – Terracotta

Many statues made in the Art Deco period were terracotta, ceramic and plaster. There were other mediums used, bronze, spelter, marble, alabaster and wood but this blog will focus on the first group, Terracotta.

During the first quarter of the twentieth century, metal was in demand for war material and so a requirement for other mediums came to the fore and terracotta, although used for centuries previously, became more prevalent, leading to many artists producing pieces in the material with the added bonus that they were sometimes the cheaper option.

Terracotta figures are very good value being considerably cheaper than the metal variants but still attain a good level of finish. Their base material, fired clay is less resilient than metal and easier to damage hence the nicer pieces are rarer to find in good condition than both spelter and bronzes. Many of the terracotta statues were also made as spelters and bronzes in the same design. Nevertheless, good examples of terracotta figures offer a cheaper start to a collection. Terracotta can be finished in a natural finish, painted or glazed.

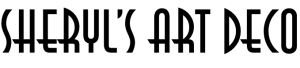

Left, is a terracotta goddess of the hunt by Lavaysse. This particular model was also produced as a bronze. (F2462 is the bronze version – and is currently available from stock).

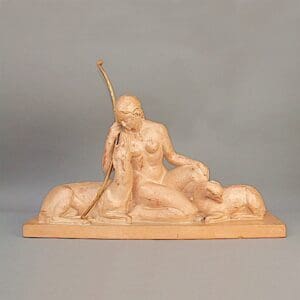

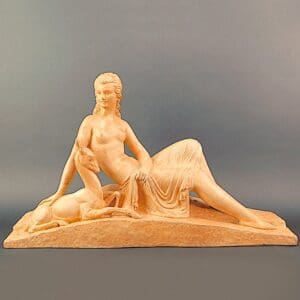

Terracotta finish statue by Demetre Chiparus (middle). The large one on the right (Awakening) can be seen in the Chiparus Book 2nd edition page 63 and is currently available on the website.

The Process

The way a terracotta statue is made varies depending on design. In research for this blog I have found that when an artist produces a bust, they would often apply the clay around a large amount of balled up newspaper. This is because a terracotta statue, before being fired in the kiln should be hollow and no thicker than one inch to avoid breaking. Once the bust is complete, the artist will slice off a section of the head, usually in the hair, carefully place the smaller piece to one side before removing the ball of newspaper from the inside. Once the newspaper has been fully removed they would begin the process of removing and smoothing out the clay inside to meet the required thickness. This is done with a clay sculpting tool. Once the thickness of the clay is consistent throughout, holes are often created into the inside surface of clay, these holes help remove steam from inside during the firing process. The earlier removed hair section is then put back in place using a clay and water mix, consistency similar to that of cream to act as a bonding agent.

The two parts would then be “pinched” all around and re-sculpted to the desired design, leaving no trace of the slice made earlier, and ready for drying. A terracotta item will shrink during the drying process so a consistent thickness is not just desired but essential. If a thick area of clay and thin area of clay are near each other, they will dry at different speeds which will likely lead to cracks.

When making statues, the clay will usually be solid until the statue is complete. Then somewhat counterintuitively holes will be dug in strategic positions, the shoulder and lower back appears to be a common place as it allows the artist to angle the sculpting tool to remove large amounts of clay from the inside with relative ease. Once happy the inside is sufficiently hollow, small amounts of clay will be placed back over the hole(s) and re-sculpted.

Most terracotta must be hollow before drying and firing, solid clay items will almost inevitably crack, split or break during the drying process.

The drying process can usually be achieved merely by leaving the item in direct sunlight for a period of time. The time needed to complete this process depends on a number of factors including the local heat and humidity.

A kiln is, at its core, an oven. Types of kilns have varied through the centuries and decades and from region to region depending on local resources available, from holes dug in the ground with natural clay placed around the outside to create a chamber to charcoal and brick built. They are primarily powered by electric, gas or wood.

Todays technology means that kilns can look very similar to a small fridge, significantly more efficient than traditional pre electric kilns as it allows temperatures to be precisely controlled and timings to be exact.

Three natural finish terracotta figures by Demetre Chiparus – all currently in stock. All three figures were also available in bronze, but with a very large price difference.

The Finishing

Although all figural items in any medium are to some degree hand finished, terracotta figures require individual hand finishing to a sometimes higher degree, unlike some of their metal models, due to the need to fire each piece after a finish is applied and therefore multiple finishes require more firing.

Paints and glazes require high temperatures to bake the finish and therefore firing cracks, fissures and even complete failures are more common with terracotta than their metal counterparts although its fair to say that even spelters were prone to failures. They are often found with holes to help hot gasses escape which would usually be filled after but not always.

Terracotta figures were often patinated as the selection below. Some were in a bare terracotta, others with a green patina were patinated to emulate bronze finishes. often the same statue can be seen with different patinas as it was up to the buyer to choose their preferred patina.

This is a Goldscheider art nouveau example of a life-size terracotta bust, this one is adorned with Cabouchon stones and metal effect clothing detail (left).

The central statue is a large lovely two-tone figure which is actually all terracotta the body has a green patina to emulate bronze and the brown base is to look like marble or wood.

The last of the 3 is a large green patinated Chiparus statue which is 69cms wide.

Further examples of terracotta plaques and busts below.

Terracotta wall masks by Goldscheider (left) and Podany (centre) and a bust by Goldscheider.

My favourite Art Nouveau bust by Johann Blasche (left), The Water Carrier by Karl Gross (centre) and a large unsigned terracotta mask – one of three that adorned the interior of a French theatre.

Finally a few other examples of our terracotta works which are wonderful examples of the medium.

Ugo Cipriani, Pierre Le Faguays and The Martel Brothers

Back to all blogs